In our first article about the future of CNC machining, we briefly introduced how robots could integrate into the industry. Now, this article will delve into more detailed and fascinating insights on the subject.

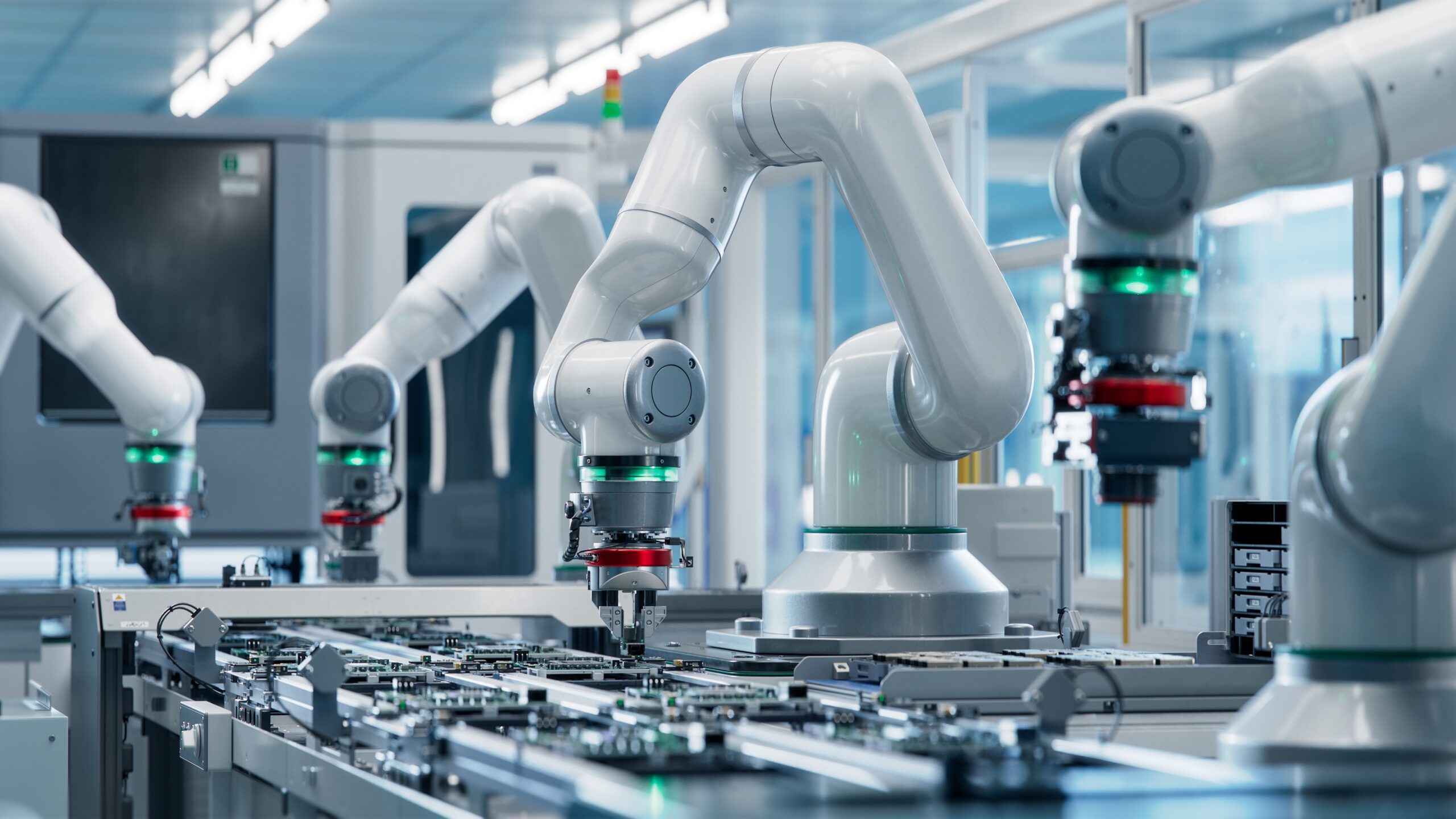

The evolution of CNC machining is marked by an extraordinary partnership between humans and machines. Cobots, at the forefront of this revolution, work alongside human operators to significantly enhance efficiency and innovation on the production floor.

*What is a cobot? A cobot (collaborative robot) is designed for direct interaction with a human within a shared space, unlike regular robots that operate independently of human intervention.

The Cobot Revolution:

Cobots, engineered for calculated and safe interaction with human colleagues, are transforming the manufacturing floor. These robotic team members are pivotal in bridging the technological gap, augmenting human capabilities at the workplace as essential tools.

In CNC machining, the collaboration between human intuition and robotic precision is critical.

Cobots excel at performing repetitive and precision tasks, allowing human operators to focus on complex setups and quality control. This ensures the high accuracy required in CNC operations, highlighting the essential role of human-robot collaboration.

Our exploration of the benefits of collaborative robots (cobots) in CNC machining provides insights on how they can enhance productivity, safety, and efficiency in manufacturing environments.

Cobots offer a promising solution for efficient machine handling, easy programming, and cost-effective operation.

An example is BW Industrie, an industrial company specializing in degreasing and processing mechanical parts, which significantly improved its production processes using Universal Robots’ cobots. By deploying four robotic arms, the company managed to handle tasks such as loading and unloading CNC lathes, quality control of metal tubes, and distribution of metal parts.

This automation enabled BW Industrie to maintain competitiveness, increase its workforce by 50%, boost its revenues by 70%, and reduce health disruption risks among workers (source: universal-robots.com).

Cobots offer more than just productivity enhancements; they also promote a healthier work environment by reducing exposure to hazardous tasks, allowing employees to focus on more cognitive tasks. Moreover, the flexibility and user-friendly interface of cobots allows quick reprogramming in the production environment to meet changing manufacturing needs.

For manufacturers looking to embrace similar technological advancements, BW Industrie’s case demonstrates the tangible benefits of integrating cobots into CNC machining workflows.

This underscores the potential of cobots to transform production floors, indicating their adoption in industries seeking innovation and competitive advantage.

To conclude, the journey of integrating cobots in CNC machining is underway, promising to revolutionize production methods. Despite challenges like training and technology adaptation, the potential for efficiency improvement, safety, and employee satisfaction is immense.

The era of human-machine collaboration in CNC machining isn’t just on the horizon—it’s here.

Cobots enhance the production process by combining human skills with robotic precision—more on this in our upcoming articles—proving that the most effective results stem from the synergy of humans and machines, benefiting the customer.

This collaborative approach not only sets a new standard for the industry and precision machining itself but also promises a future where innovation and worker welfare go hand in hand.

Contact us for more information about our machines, work methods, and production facilities.

Click here – Contact Us